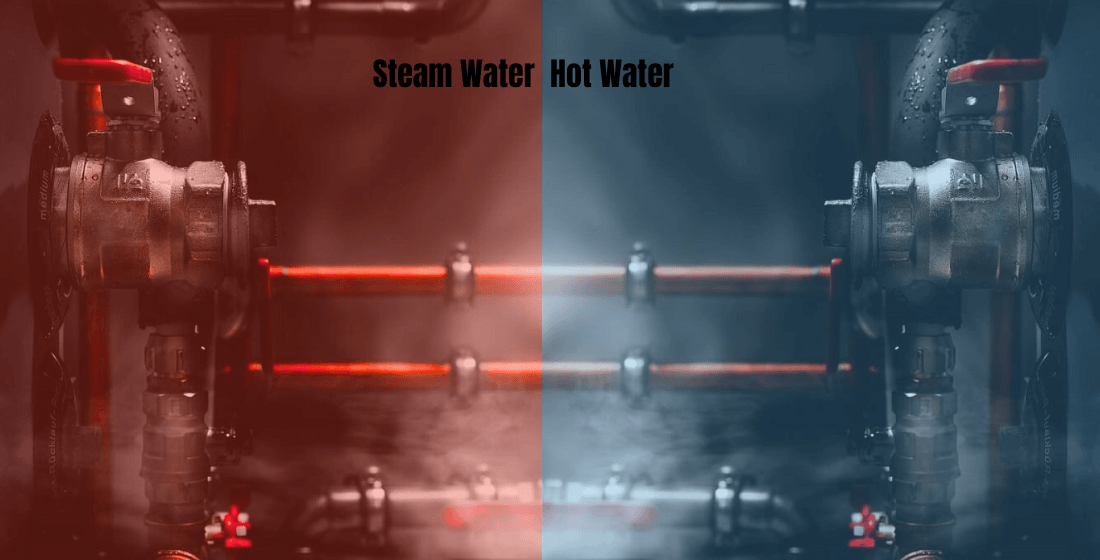

Converting from steam to hot water is gaining traction in residential, commercial, and industrial spaces due to its potential for energy efficiency, cost savings, and environmental benefits. This shift addresses both modern energy needs and sustainability goals. In this blog, we’ll explore the principles of steam-to-hot-water conversion, its advantages, challenges, and the process to make such a transition successful.

Understanding Steam and Hot Water Heating Systems

A steam heating system operates by heating water in a boiler until it produces steam, which is transmitted through the radiator or other heating mechanisms. It is a strong system, but usually less efficient due to heat loss and the older infrastructure of the ancient system.

In contrast, a hot water system transmits warm water in pipes for heat supply. Since the water is colder than the steam system, less energy is lost, and better management of distributing heat is achieved. Systems are common in modern buildings due to flexibility, energy efficiency, and compatibility with renewable energy resources.

Benefits of Converting from Steam to Hot Water

- Energy Efficiency: Low-temperature warm water systems reduce heat loss in distribution. They have low energy requirements for heating, thus receiving adequate energy savings in the long term.

- Cost Savings: Energy Use Adaptation, property owners enjoy the low utility bill. Maintenance allegations also decrease because hot water systems are less prone to mechanical wear than leaks, rust, and steam systems.

- Improved Comfort and Control: Hot water systems provide better temperature control, which provides similar and comparable heat in a space. Control and zoning features of modern systems allow for to sew of heat for unique needs.

- Environmental Benefits: Better hot water system efficiency reduces greenhouse gas emissions. They are more favorable to modify renewable energy technologies such as solar thermal systems.

- System Longevity: Hot water systems are more optimal and long -longer lifespan, causing continuous replacement or full-scale repair.

Challenges of Conversion

While the benefits are compelling, converting from steam to hot water does come with challenges:

- Initial Costs: The upfront investment for system redesign, new piping, and equipment can be significant. However, these costs are often offset by long-term savings.

- Building Compatibility: Older buildings may require extensive retrofitting, including changes to radiators, pipe systems, and boiler configurations.

- Technical Complexity: Conversions require careful planning and expertise to ensure compatibility between old and new components and to prevent issues like uneven heating or leaks.

- Disruption During Installation: Retrofitting an existing system involves temporary disruptions to normal operations, which may be inconvenient for occupants.

Steps for a Successful Conversion

- Assessment and Feasibility Study: Start with a thorough evaluation of the existing steam system to determine its condition and compatibility with hot water infrastructure. Consult with heating engineers or energy consultants to identify potential challenges and solutions.

- System Design: Develop a detailed plan that outlines the modifications required for radiators, piping, and boilers. Advanced design software can help simulate performance and identify any issues.

- Upgrade Equipment: Replace outdated steam boilers with modern hot water boilers. Ensure the selected equipment meets energy efficiency standards and is suitable for the building’s heating load.

- Retrofitting Infrastructure: Modify or replace radiators, install new piping where necessary, and integrate advanced control systems for zoning and temperature regulation.

- Testing and Optimization: After installation, thoroughly test the system to ensure optimal performance. Adjust settings and fine-tune controls to maximize efficiency and comfort.

- Monitoring and Maintenance: Establish a maintenance plan to keep the system running efficiently. Regular inspections can prevent issues and prolong the life of the system.

Conclusion

Converting from a steam to a hot water heating system is a forward-thinking decision that aligns with modern energy efficiency and sustainability goals. Despite the upfront investment and technical challenges, the long-term benefits, ranging from reduced energy costs to environmental impact, make it a worthwhile endeavor. With proper planning, expert guidance, and attention to detail, this transition can transform an outdated heating system into a modern, efficient, and eco-friendly solution that serves the needs of today and the future.

For building owners and facility managers, the conversion is not just a step toward operational efficiency but a meaningful contribution to a greener and more sustainable world.

We specialize in delivering energy-efficient, code-compliant heating system designs tailored to your building’s specific needs. Whether you’re planning a full steam-to-hot-water conversion, need feasibility consulting, or want to discuss customized solutions for your franchise or commercial property, we’re here to help.

How to Convert from Steam to Hot Water Heating Systems

- Evaluate the Existing System

Begin with a professional assessment of your current steam system. Check the age, condition, and configuration of boilers, radiators, and piping.

- Conduct a Feasibility Study

Consult a licensed MEP engineer or HVAC specialist to analyze the building’s readiness for conversion. They will identify risks, costs, and potential design solutions.

- Design the New System

Create a detailed system layout that includes hot water boiler sizing, new or adapted piping, and compatible heat emitters. Incorporate zoning and smart control technologies for efficiency.

- Secure Permits and Approvals

Depending on your location, building codes may require permits for modifications. Work with professionals to ensure all designs meet local and state codes.

- Procure and Install New Equipment

Replace the steam boiler with a high-efficiency hot water boiler. Install insulated piping and new or modified radiators or baseboard units.

- Test the System Thoroughly

Once installed, test for proper pressure, flow rate, temperature control, and leak detection. Fine-tune settings for optimal performance.

- Train Staff and Schedule Maintenance

Educate building personnel on the new system’s operation and establish a preventive maintenance plan to ensure long-term efficiency.

Frequently Asked Questions (FAQ)

The timeline varies based on building size and system complexity, but typical conversions take 4 to 12 weeks, including design, permitting, and installation.

Yes. While the upfront investment can be substantial, most property owners experience 20–30% energy savings, which pays back over time through reduced utility bills and maintenance costs.

Sometimes. Cast iron radiators can be reused if they are in good condition and compatible with hot water flow. However, modifications or replacements are often needed for optimal performance.

Yes, but disruptions can be minimized with careful planning and phased installation. Temporary heating solutions can also be arranged if necessary.

Absolutely. Energy-efficient systems and modern controls enhance building performance and appeal to environmentally conscious buyers and tenants.

Yes. Hot water systems are compatible with solar thermal panels, geothermal heat pumps, and other sustainable technologies, making them ideal for green building goals.

Work with licensed MEP engineers or HVAC firms experienced in steam-to-hot-water conversions. They ensure code compliance, energy optimization, and seamless integration.

No comment